Live

- State government to Supreme Court: New guidelines on how to apply anti-gangster law in UP

- CM Chandrababu to unveil Vision 2047 document today in Vijayawada, traffic restrictions imposed

- State-level LIMES-2k24 inaugurated

- UP to establish ‘Har Ghar Jal’ village at Mahakumbh 2025

- NDA needs support of 361 LS MPs: Cabinet gives nod to bill for 'one nation one election'

- Kejriwal woos women voters with Rs 2100

- Transforming leftovers: 2 innovative recipe ideas

- MLA seeks shipbuilding industry at Chinnaganjam

- Papon marks 20 years in music: A journey of soulful versatility

- Jasleen Royal to collaborate with Coldplay at ‘Music of the Spheres World Tour’

Just In

Scientists at the Indian Institute of Chemical Technology (IICT) have developed a unique membrane that promises to reduce the cost of dialysis by 50 per cent. At present, the dialysis membrane modules are imported.

A feather in IICT cap

Hyderabad: Scientists at the Indian Institute of Chemical Technology (IICT) have developed a unique membrane that promises to reduce the cost of dialysis by 50 per cent. At present, the dialysis membrane modules are imported. Renal replacement therapy is too expensive to be afforded by majority of people afflicted with chronic kidney disease (CKD). The IICT scientists have developed a dialysis membrane module that comes to the aid of people to get the treatment at an affordable price.

- Renal replacement therapy is too expensive to be afforded by major of people

- People with chronic kidney disease are forced to shell out money for dialysis too because imported kits are very costly

- Indian Institute of Chemical Technology scientists have developed a unique membrane which cuts down the cost by 50 per cent

Dr S Sridhar, Principal Scientist and project leader, Membrane Separations Group, Chemical Engineering division, IICT said, “The thin hollow fibre membrane developed at IICT allows selective removal of metabolic toxins, such as urea and creatinine.” Dialysis is a process of removing waste and excess water from the blood in people suffering from CKD. Each dialysis session lasts three hours and a patient requires treatment two to three times a week.

Due to high cost, patients as well as laboratories resort to using the same kit multiple times which can be dangerous and lead to Hepatitis C. “When the cost reduces by half people will stop using the same kit repeatedly,” said Dr Laxmi Gayatri, DST scientist and member of the Membrane Separations Group.

Annually over two lakh people in the country develop kidney failure and the number is expected to reach 100 million by 2030. The imported dialysis membrane costs Rs 700 and the IICT product could be made available at between Rs 150 and Rs 200 if large scale production is taken up. IICT has applied for a patent and is looking forward to partnership with industry for large-scale production.

Ninety per cent of people with kidney failure in India, die within months due to lack of treatment and this innovation could save and prolong life of millions, said scientists. Over 600 million people cannot afford renal replacement resulting in one million deaths annually from untreated kidney failure.

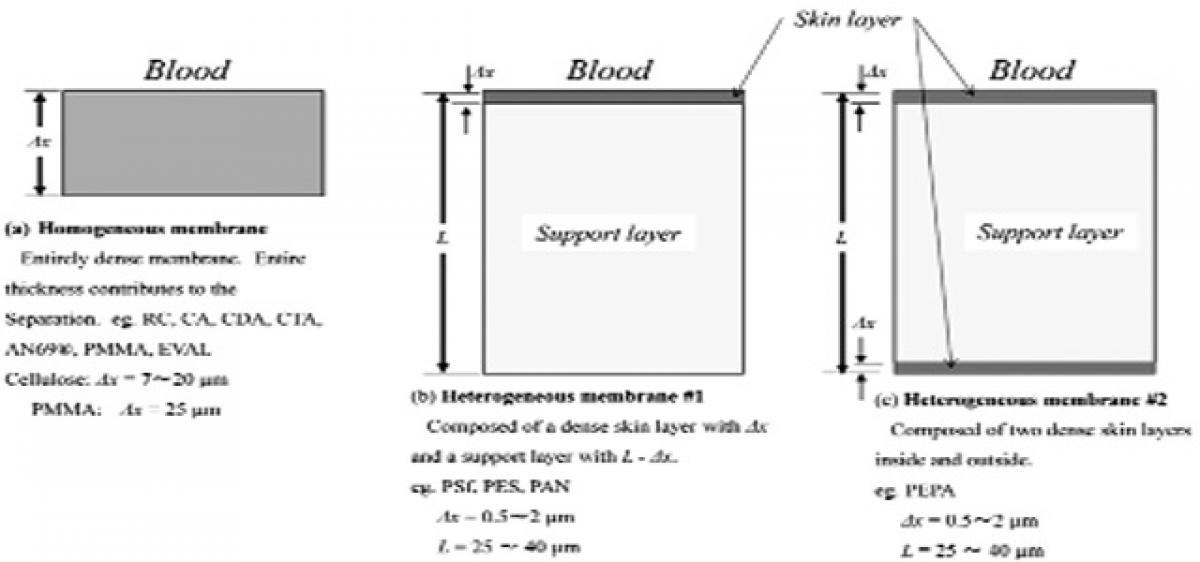

Dr Sridhar said, “A spinneret was developed that excludes imported fibre. Poly (ether sulphone) material was used to develop ultra thin hollow fibres for dialysis with dimensions of 200 to 250 micron outer diameter of fibres. This does the same job and even more efficiently than the imported membrane. In addition, it can be modified by using additives and help in anti-clogging properties. Blood will not clot during dialysis.” He further added that hollow fibres are produced for water purification and not for dialysis. So the design for the spinneret had to be precise.

By T P Venu

© 2024 Hyderabad Media House Limited/The Hans India. All rights reserved. Powered by hocalwire.com