Zaidi keeps alive age-old technique of glass making

The ageold traditional craft of making decorative items by blowing the glass mould is kept alive in this part of the City, which otherwise is found only in Cities of middleeast and Central Asian countries Despite the availability of machinemade glassware, these artifacts made by blowing molten glass remain in demand because of its artistic value

Dabeerpura: The age-old traditional craft of making decorative items by blowing the glass mould is kept alive in this part of the City, which otherwise is found only in Cities of middle-east and Central Asian countries. Despite the availability of machine-made glassware, these artifacts made by blowing molten glass remain in demand because of its artistic value.

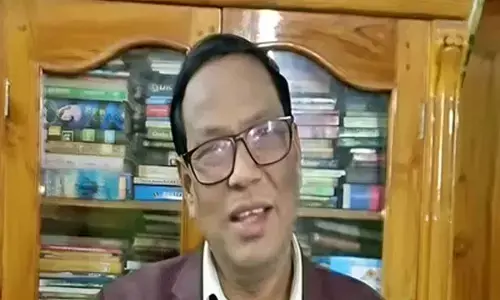

Zaidi Glass Products in Noorkhan Bazar is famous for making glassware with the unique technique of ‘blow-molding’ and is patronized by the sizeable population in the parts of Old City for over four decades. “In 1974, this work of glass decoration was started by father and his elder brother. I learnt the technique and started by doing myself for the past 30 years,” said Syed Jaffer Ali Zaidi, a state awardee in this category.

He explained that all glass items from big to small are made with this centuries-old technology. In this process different kinds of instruments are used, where the artist should be engaged in precision of handiwork to transform the mould into a beautiful design. The raw material used by the family of craftsmen is glass cubes which are available with the local dealers, besides soldering gas and oxygen. For making the glass mould, the material is burnt at 600 degree Celsius and above. Then the molten glass is blown and with the help of some tools, the melted glass is slowly transformed into an attractive artefact.

The glass blowing work is now done by silicate glass tube whose size ranges from 4mm to 100mm. The other types of tools are twisters, surgical instruments and some other tools to come up with a desired shape and design. The other equipment used during the process is gas cylinder, oxygen cylinder, burner, carbon rods and knives of different shapes and sizes. “It takes minimum 2 hours for the entire process which includes drying up of the glass towards making a single small item. For this 30 per cent of the glass will be wasted,” said Syed Jaffer.

Different items are made depending on the precision with which an artist can transform the hot glass mould. Glass articles are regularly made by the craftsman of sizes ranging from 3 in to about 4 ft. He moulds the glass from the size of a pen and other decorative items like huge flower vases. He regularly receives orders for making religious articles, glass bowls, fish pots, also Charminar and several other decorative items, whose price ranges from Rs 30 to Rs 25,000 (2 ft glass Charminar, which was recently made).

Sometimes these articles are also decorated with 18 carat gold plated on glass, on demand. With the flooding of glassware from China, the artist feels that the age-old traditional blow-moulding art may lose its sheen. Thanks to the support from some government agencies, he is able to sustain the onslaught of machine-made Chinese articles.

BY MM Farooqui