Kalamkari: The art is fighting for its survival

The aged old Kalamkari printing work on pure cotton cloth with natural colours without using any chemicals won the appreciation of people worldwide, and the Kalamkari art form found a place in Victoria and Albert Museum, London, Royal Ontario Museum, Canada, The Metropolitan Museum of Art, New York and Rijks museum, Netherlands. The Kalamkari print art form still survives in Machilipatnam surrounding Pedana village and is turned into a livelihood for nearly ten thousand people, most of whom are women

PV Krishna Rao & Y Brahmaji

Kalamkari printing which has world recognition is now a livelihood for many women in the Machilipatnam district. The aged old Kalamkari printing work on pure cotton cloth with natural colours without using any chemicals won the appreciation of people worldwide, and the Kalamkari art form found a place in Victoria and Albert Museum, London, Royal Ontario Museum, Canada, The Metropolitan Museum of Art, New York and Rijks museum, Netherlands. The Kalamkari print art form still survives in Machilipatnam surrounding Pedana village and has become a livelihood for nearly ten thousand people, the majority of whom are women.

Though facing competition from mechanised printing works and artificial chemical colours, most people in Pedana still depend on hand printing of natural colours with wooden blocks in a traditional way, which attracts export opportunities of Kalamkari works. The Kalamkari art printing cloth is being exported to USA, Japan, Germany, Netherland, France and several metro cities of North India.

Speaking to The Hans India, a Kalamkari artisan Pichuka Srinivas, who recently won Dr YSR achievement award from the state government, said that they still prefer to follow the natural colours printing with wooden blocks. Explaining the process of Kalamkari printing, he said that they use Myrobalan, Savalakodi (oldenlandia umbleta) Danimma Berudu (Palmogranite peel), Surali Pattai ( Ventilago Madraspatna), Moduga flower (Butea Frondosa), Nalla Kanchu (Mimosa Catechu) and Thummachekka (achacia Arabica).

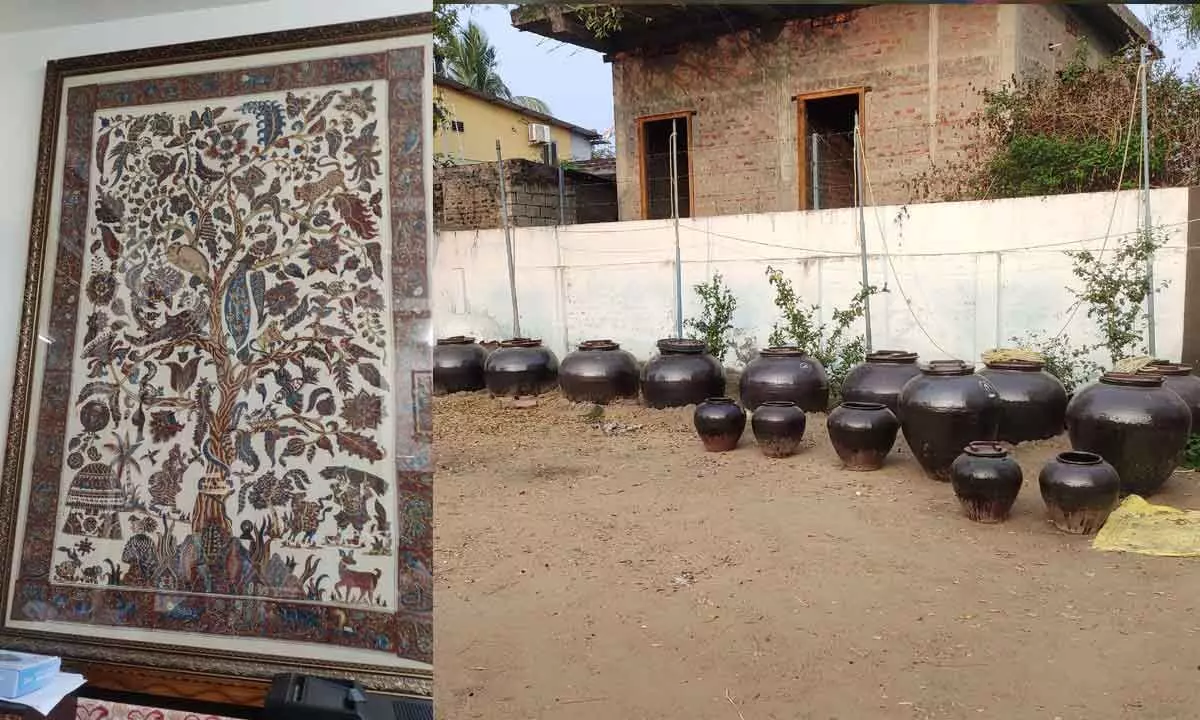

Stating that it is a long process of 21 days to complete the Kalamkari print works, the artisan said that they use Burmese pots for the fermentation of natural colours. They purchased cotton cloth of 100 metres from Coimbatore and other areas of Tamil Nadu. At first, they give cow dung treatment and natural bleaching to the fabric before printing work, followed by Myrabalan treatment and kalamkari print. After completion of the print, the cloth will be washed in flowing water like canals and dried. Later the fabric will be boiled; then starch will be applied before the second colour printing and given alum treatment. They follow different traditional methods to get different shades with natural colours.

The Kalamkari art printing works products, including bed covers, table covers, cushion covers, Noreen curtains, aprons, round table covers, flood cushions, bags, kerchiefs, have more demand both in the country and abroad.

A woman worker Durga said that the Kalamkari printing works provided them employment. She said most women in Pedana region know the art of Kalamkari printing. They have more demand during summer as the weather is suitable for colour printing and drying works. She said that the government should provide financial assistance to Kalamkari artworks on par with weavers.

Now the third generation, entering the ancient Kalamkari art form, seeks government cooperation to continue art. An engineering graduate P Varunkumar said that the government should wave GST to survive Kalamkari artworks. Another senior Kalamkari artisan P Koteswara Rao said, "Now, we are paying 5 per cent GST, and there should not be GST for Kalamkari art printing works as they use pure cotton and hand-woven cloth and Kalamkari prints with natural colours following Gandhian principles."